CNC Milling & CNC Turning you are interested in

CNC Milling

CNC milling refers to a type of computer aided controlled machining that uses rotary tools to make cuts at materials during the manufacturing process. The machine reads the geometric code from the CAD file and replicates the design using the machine tools with high accuracy.

CNC Mills can be used for many geometries. The workpiece is held rigidly in a jig or vice, and the mill head moves in the 3 axis plane to remove the material using high-speed rotary tools or drills.

Due to the limited range of motion, they are relatively easy to operate and program, so set-up costs are low compared to other CNC processes.And the limited range of movement means that there are some limits to the manufacturing process.This can be overcome by using the machine tools to reorientate the part, but each adjustment in the manufacturing process adds extra time and risks possible error, meaning that costs can increase.

What is CNC turning?

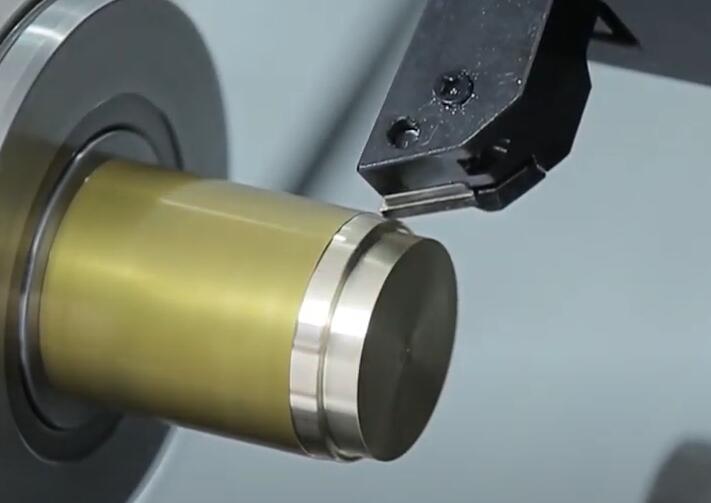

CNC turning is a particular form of precision machining in which a cutter removes material by making contact with the spinning workpiece. The movement of the machinery is controlled by computer instructions, allowing for extreme precision and repeatability.

Turning is different to CNC milling, in which the cutting tool rotates and is directed from multiple angles at the workpiece, which is usually stationary. Because CNC turning involves rotating the workpiece in a chuck, it is generally used to create round or tubular shapes, achieving far more accurate rounded surfaces than would be possible with CNC milling or other processes.

The tooling that is used with a CNC lathe machine is mounted to a turret. This component is programmed to make certain movements and remove material from raw materials until the desired 3D model is formed.

CNC Turning

CNC turning is a high accuracy computer-aided manufacturing process in which the material making up the workpiece is held and rotated by the machine while the tool chips at it to create the desired shape. This type of controlled machining produces parts at a higher rate than CNC milling.

CNC turning is commonly used for mechanical and aspect components, which are often made from the most machinable metal-aluminum. Aluminum parts can be made with high strength, accuracy, and superior surface finish.

CNC turning machines work by holding the workpiece on a spindle and rotating them at high speed. The cutter used is typically a blade, unlike the rotary cutters used in CNC milling.

Due to the nature of the manufacturing process, this kind of CNC machining can only produce revolved or rotationally symmetrical parts along with a central access (cylindrical parts and threads). If a more complex design is required, the part will often then be transferred to a CNC mill for further controlled machining.

售前客服

售前客服